Aluminum Casting Techniques: a Deep Study Materials and Approaches for Success

Aluminum casting techniques play an essential function in production. Different approaches exist, each matched to various applications and requirements. Sand casting is preferred for bigger elements, while die casting is recognized for its precision in high-volume production. Investment casting offers comprehensive layouts with superior finishes. Comprehending these differences can greatly affect task end results. Precision aluminum casting. However, selecting the suitable method is not always simple, bring about crucial factors to consider that should be checked out better

Recognizing Aluminum Casting: A Summary

Aluminum casting is a crucial production process employed throughout different sectors to develop elaborate elements with high precision. This technique entails putting molten aluminum into a mold and mildew, permitting it to strengthen and take the form of the desired component. The flexibility of aluminum, integrated with its corrosion-resistant and light-weight residential or commercial properties, makes it an optimal choice for applications in automotive, aerospace, and consumer products.

Various casting methods exist, each suited to specific requirements and task scales. Aspects such as mold products, cooling rates, and the intricacy of the layout play a considerable duty in determining the most reliable approach. Furthermore, the properties of the aluminum alloy made use of can impact the end product's toughness, longevity, and surface finish.

Comprehending the principles of aluminum casting makes it possible for suppliers to enhance manufacturing processes, minimize waste, and assurance premium output, which is necessary in today's affordable market.

Sand Casting: Applications and methods

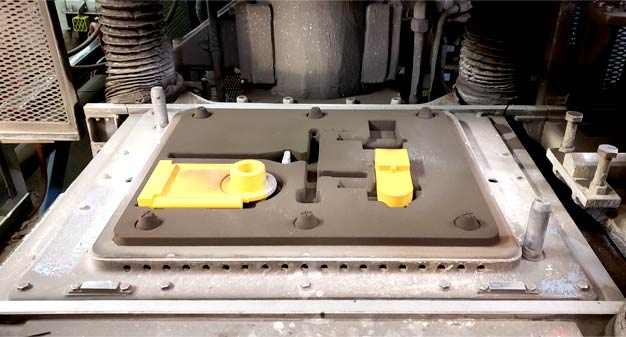

Amongst the different techniques used in aluminum casting, sand casting stands out due to its adaptability and cost-effectiveness. This method includes developing a mold from a blend of sand and binder, which can be shaped to fit complex designs. Once the mold is ready, liquified aluminum is poured right into it, enabling for elaborate features and information to be caught.

Sand casting is specifically advantageous for generating big parts and low-volume manufacturing runs, making it perfect for vehicle components, machinery parts, and creative sculptures. The method also suits a variety of aluminum alloys, improving its flexibility in various applications. Additionally, making use of sand as a mold and mildew material allows for very easy improvement and reuse, adding to eco lasting techniques. Nonetheless, attaining high dimensional precision can provide challenges, requiring knowledgeable craftsmanship and careful control of the casting process. On the whole, sand casting continues to be a fundamental technique in aluminum factories worldwide.

Die Casting: Precision and Efficiency

Die casting is a very reliable approach of producing aluminum parts with remarkable dimensional precision and surface finish. This procedure involves forcing liquified aluminum right into a specifically machined mold and mildew under high stress, which permits elaborate layouts and marginal product waste. The quick cooling of the alloy within the mold and mildew causes a solidified component that usually requires little to no extra machining.

Die casting is particularly beneficial for high-volume production runs, where uniformity and speed are paramount. It sustains the creation of complex geometries, making it appropriate for various applications, consisting of auto, aerospace, and durable goods.

Furthermore, the process can accommodate numerous aluminum alloys, boosting the mechanical buildings of the finished products. With its capability to generate lightweight yet durable parts, die casting attracts attention as a favored strategy in modern production, providing both precision and performance in aluminum casting.

Financial Investment Casting: Detail and Intricacy

Investment casting, additionally referred to as lost-wax casting, is a exact and flexible technique for generating intricate aluminum parts. This strategy is especially valued for its capacity to develop detailed geometries and fine details that are commonly unattainable via various other casting methods. The process begins with a wax pattern, which is covered in a ceramic shell. Once the shell hardens, the wax is dissolved, leaving a comprehensive mold for aluminum pouring.

The benefits of financial investment casting consist of exceptional surface finish and dimensional accuracy, reducing the requirement for considerable machining later. It is especially useful for little to medium production runs where precision is critical. This method suits different aluminum alloys, improving its applicability throughout sectors. aluminum casting. Ultimately, financial investment casting sticks out for its ability to click here now deliver both visual allure and practical performance in aluminum components, making it a preferred choice for designers and designers seeking facility services

Picking the Right Method for Your Job

Exactly how can one establish the most suitable aluminum casting technique for a certain project? The choice process hinges on several important factors, including the complexity of the style, the desired surface area coating, and manufacturing volume needs. For intricate designs, financial investment casting usually proves helpful as a result of its capability to capture fine information. Alternatively, sand casting might be preferred for larger, less intricate parts, providing cost-efficiency and flexibility in manufacturing.

Furthermore, considerations pertaining to tolerances and mechanical residential or commercial properties of the end product are necessary. For high-performance components, die casting might be the very best selection, as it provides premium dimensional accuracy and surface high quality. Furthermore, recognizing the material buildings and compatibility with the chosen approach is very important for guaranteeing the success of the project. Eventually, a comprehensive evaluation of these aspects will direct the decision-making process, causing one of the most reliable aluminum casting approach for the specific project handy.

Frequently Asked Inquiries

What Is the Ecological Influence of Aluminum Casting Methods?

Exactly How Can I Boost the Surface End Up of Cast Aluminum?

To improve the surface area coating of cast aluminum, one can utilize strategies such useful content as sandblasting, polishing, and applying layers. Correct mold and mildew style and temperature control also significantly improve the final surface area top quality of the cast item.

What Security Preventative Measures Should Be Taken Throughout Aluminum Casting?

During aluminum casting, important security precautions include using protective gear, guaranteeing correct ventilation, utilizing fire-resistant products, preserving a safe range from liquified steel, and sticking to equipment safety and security methods to stop mishaps and injuries.

Just how Do I Troubleshoot Usual Casting Defects?

To troubleshoot usual casting defects, one must inspect the mold and mildew for damages, analyze the alloy make-up, check putting temperature, adjust cooling prices, and warranty proper airing vent to lessen air entrapment and improve casting top quality.

What Are the Prices Connected With Different Aluminum Casting Techniques?

The prices linked with various aluminum casting techniques differ significantly, influenced by aspects such as material costs, equipment, production, and labor scale. Spending plan factors to consider are necessary for choosing the most suitable casting method for details jobs.

Sand casting is favored for bigger parts, while die casting is understood for its precision in high-volume manufacturing. Amongst the various strategies used in aluminum casting, sand casting stands out due to its adaptability and cost-effectiveness. Die casting is a highly efficient approach of generating aluminum elements with phenomenal dimensional accuracy and surface area finish. Investment casting, additionally understood as lost-wax casting, is a functional pop over to these guys and accurate technique for producing complex aluminum components. How can one establish the most suitable aluminum casting approach for a specific job?